Robust Frame Assembly

The starting point for any chesterfield or club chair is the frame. This is constructed of only the finest hardwoods selected for strength and longevity. The chesterfield frame components are hand formed by time served craftsmen to give us the ready components. These components are then assembled by hand, using dowels, screws, and corner blocks for added strength. Once the chesterfield frame has been fully assembled, it is then quality checked for squareness and shape. The frame is then passed to the polisher to apply the next process.

Wood Polishing

At this point, we have a fully assembled chesterfield or club chair frame. It is now time to start the first finishing process known as polishing or French polishing. This finish is applied to any part of the chesterfield or club chair frame which will be exposed at the point of completion — such as legs, feet, etc. It is applied by hand in several coats. As the polish must be allowed to fully harden, the furniture is stored in a temperature controlled environment for around 48 hours.

Springs and Padding

This is the stage in the process where the chesterfield or club chair will really take shape. Depending on the style of sofa or chair being built, the first thing is to spring the frame. This is a painstaking process of applying individual coil springs or serpentine springs to the frame to ensure a long lasting shape to the piece of furniture. Once this stage is completed, the padding is made to pattern to suit the item and is applied, panel by panel, until the chesterfield or club chair has a finished shape.

The Upholstery

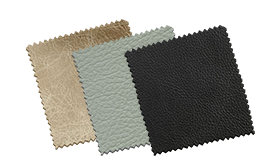

It is now time to upholster your chesterfield or club chair. Firstly, we select from our leather stores, fine grain hides in the required finish. Templates are then applied to the hides and the panels cut by the dedicated pattern maker. These panels are then passed to the upholsterer, to be applied to the chesterfield or club chair. Depending on the level of complexity of the model you have selected, this process can take up to 3 days to complete.

The Finish

The final stage in the production of your Chesterfield or Club Chair is the finish. This stage involves the buttoning and studding of the piece. Unlike many other manufacturers, Distinctive Chesterfields still uses traditional methods. We use individual studs on each piece we create — approximately 300 -1200 per item! The whole piece is then buffed or rubbed off — depending on the selected leather finish and then sealed so as to protect the achieved look.

This process from start to finish is performed under one roof — no single element being outsourced or mass produced.

When you buy a Distinctive Chesterfield, you are buying a hand built, hand crafted piece of fine English furniture.